TARGETRY

Unique capabilities for nozzle manufacturing

SourceLAB developed a range of solutions for nozzle manufacturing and characterization:

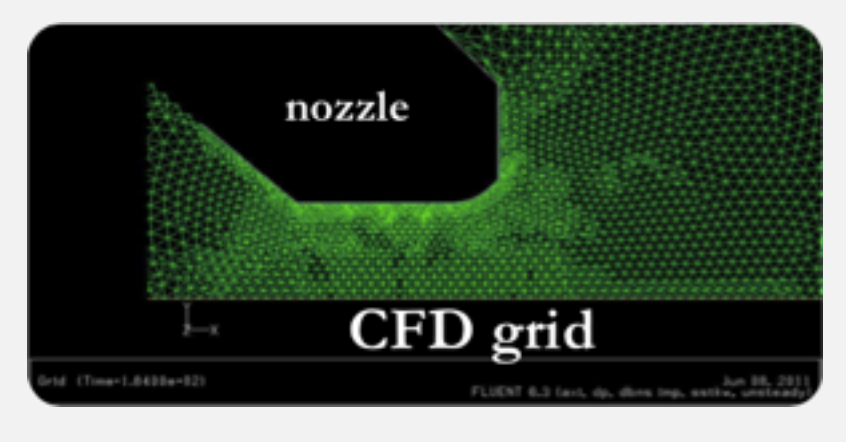

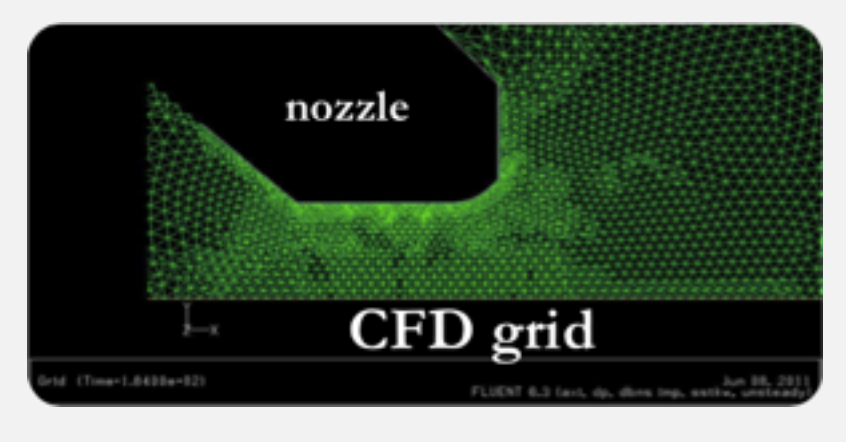

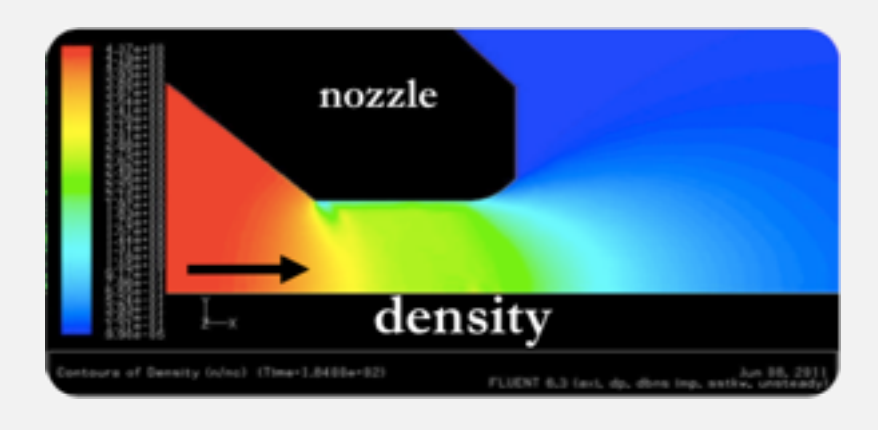

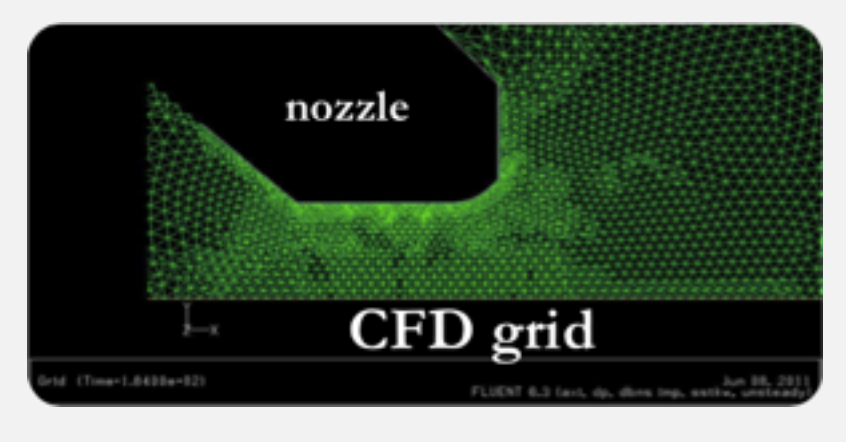

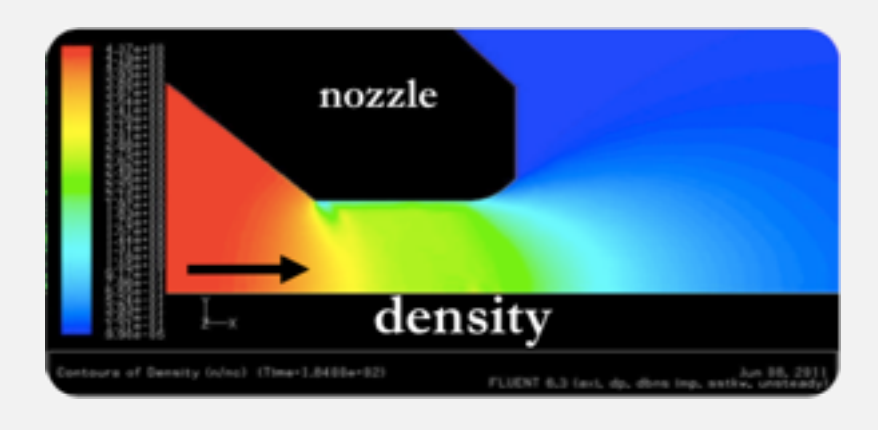

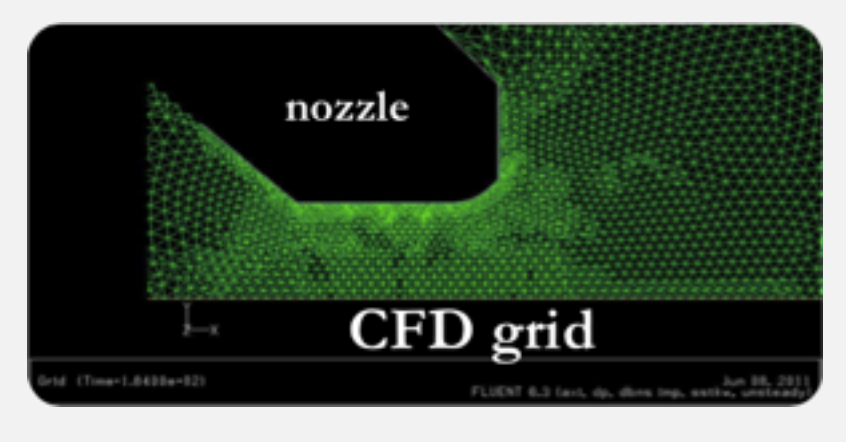

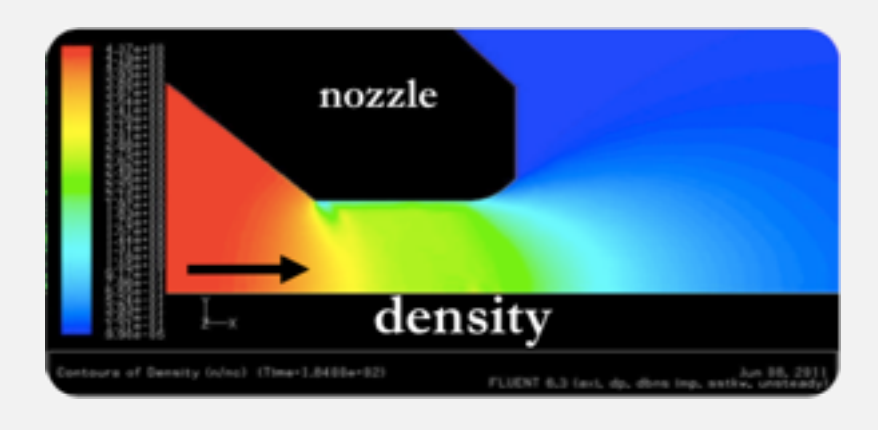

Flow simulation

- From a CAD file or specifications

Manufacturing

- Metal, ceramic, 3D printing

- Down to 30 µm hole with complex shapes

- SS manufacturing up to 58 HRC

Characterization

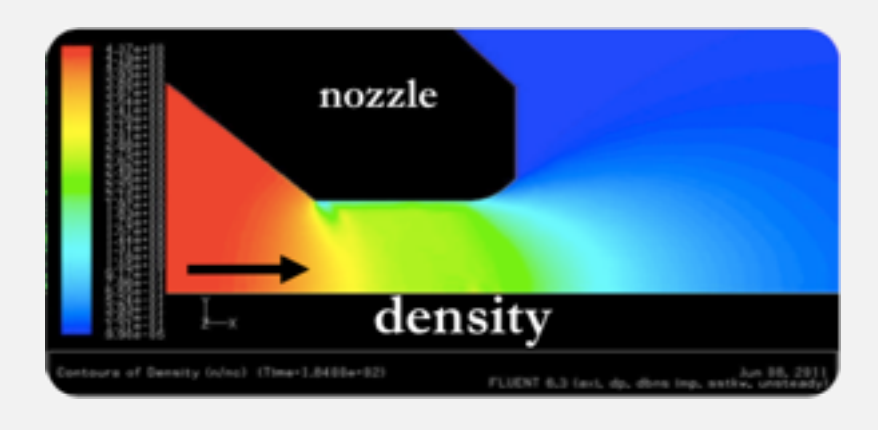

- Density profile

- Interferometry from Phasics

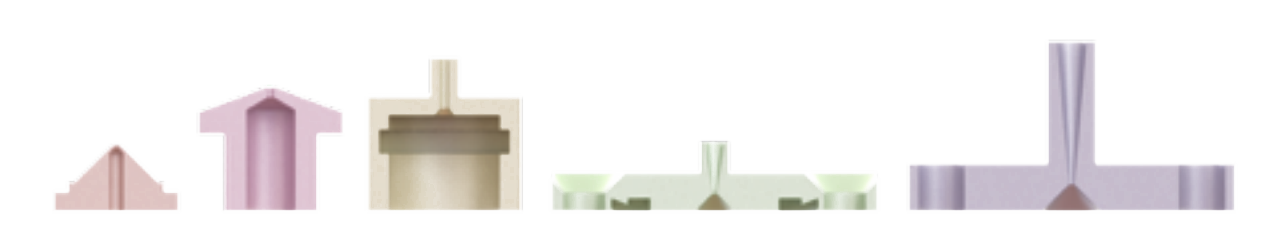

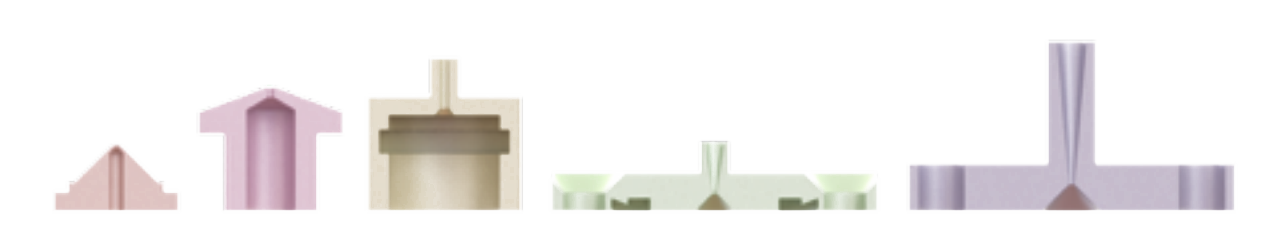

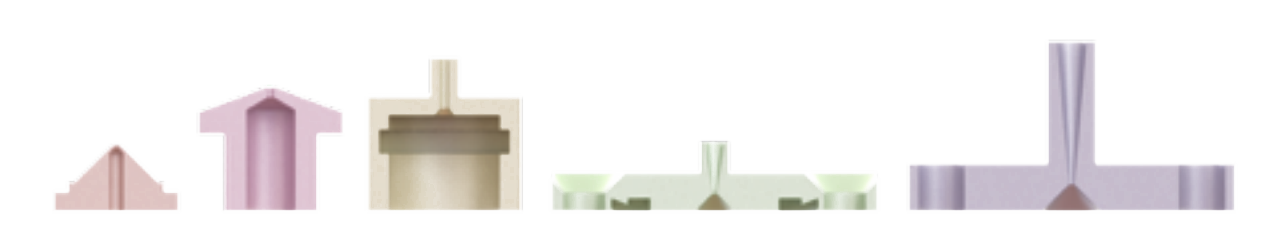

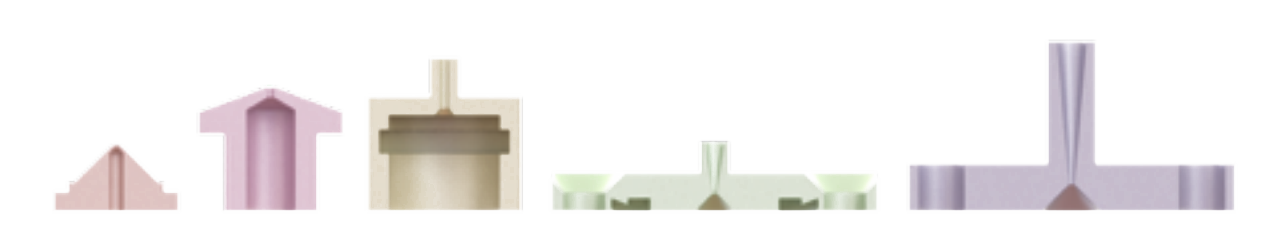

Examples of nozzles complex shapes manufacturing

Specific nozzles for interaction regimes

To make it possible for the experimentalist to explore precise interaction regimes and physics, SourceLAB developed a unique class of nozzles associated to precise manufacturing capabilities, that give access to specific plasma shapes and densities.

Each nozzle of the class can be easily fixed on a rapid valve to get the desired output flow.

In particular, our new class SL-Noz-Comp (see specifications), is specially designed to generate sub- 100 μm plasma of near-critical density, without external shocks from blades or cooling devices.

Importantly, it produces sub-μm dense plasmas at a larger distance from the nozzle exit than the standard 400 μm sonic nozzle. Therefore the lifetime of the nozzle is significantly increased while ensuring outstanding performances.

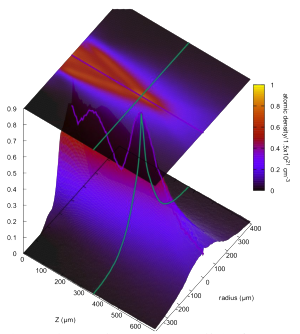

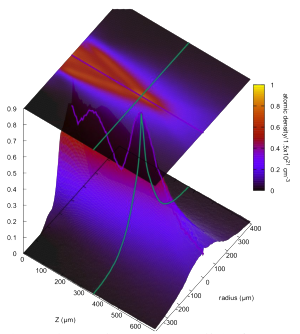

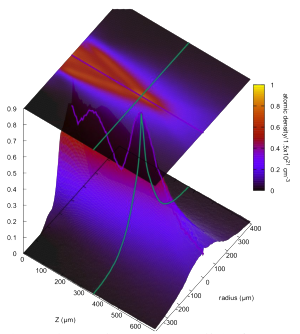

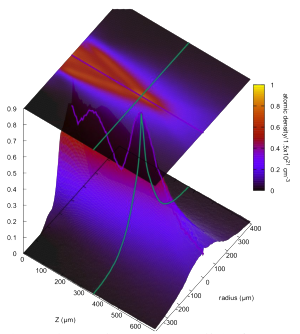

Corresponding atomic density map and projection measured at the exit.

The backing pressure reads 320 bar.

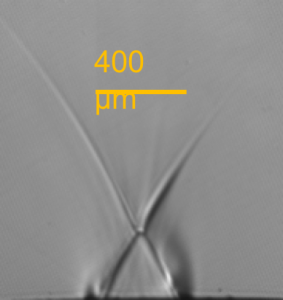

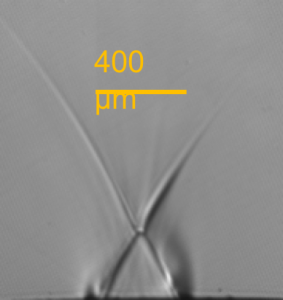

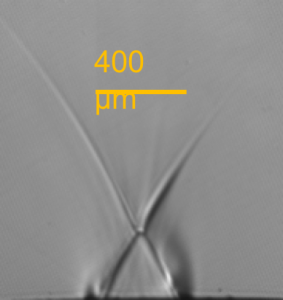

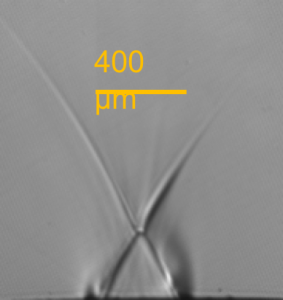

Shadowgram of a typical SL-Noz-Comp jet in vacuum.

Detailed specifications:

- L. Rovige et al.

Symmetric and asymmetric shocked gas jets for laser-plasma experiments

Rev. Sci. Inst., 92, 083302 (2021)

- J.Faure et al.

A review of recent progress on laser-plasma acceleration at kHz repetition rate

Plasma Phys. Control. Fusion 61 014012 (2019)

- D. Gustas et al.

High-charge relativistic electron bunches from a kHz laser-plasma accelerator

Phys. Rev. Accel. Beams 21, 013401 (2018)

- Overview

-

Unique capabilities for nozzle manufacturing

SourceLAB developed a range of solutions for nozzle manufacturing and characterization:

Flow simulation

- From a CAD file or specifications

Manufacturing

- Metal, ceramic, 3D printing

- Down to 30 µm hole with complex shapes

- SS manufacturing up to 58 HRC

Characterization

- Density profile

- Interferometry from Phasics

Examples of nozzles complex shapes manufacturing

Specific nozzles for interaction regimes

To make it possible for the experimentalist to explore precise interaction regimes and physics, SourceLAB developed a unique class of nozzles associated to precise manufacturing capabilities, that give access to specific plasma shapes and densities.

Each nozzle of the class can be easily fixed on a rapid valve to get the desired output flow.

In particular, our new class SL-Noz-Comp (see specifications), is specially designed to generate sub- 100 μm plasma of near-critical density, without external shocks from blades or cooling devices.

Importantly, it produces sub-μm dense plasmas at a larger distance from the nozzle exit than the standard 400 μm sonic nozzle. Therefore the lifetime of the nozzle is significantly increased while ensuring outstanding performances.

Corresponding atomic density map and projection measured at the exit.

The backing pressure reads 320 bar.

Shadowgram of a typical SL-Noz-Comp jet in vacuum.

- Specifications

-

Detailed specifications:

- Downloads

- Publications

-

- L. Rovige et al.

Symmetric and asymmetric shocked gas jets for laser-plasma experiments

Rev. Sci. Inst., 92, 083302 (2021)

- J.Faure et al.

A review of recent progress on laser-plasma acceleration at kHz repetition rate

Plasma Phys. Control. Fusion 61 014012 (2019)

- D. Gustas et al.

High-charge relativistic electron bunches from a kHz laser-plasma accelerator

Phys. Rev. Accel. Beams 21, 013401 (2018)

- L. Rovige et al.

Unique capabilities for nozzle manufacturing

SourceLAB developed a range of solutions for nozzle manufacturing and characterization:

Flow simulation

- From a CAD file or specifications

Manufacturing

- Metal, ceramic, 3D printing

- Down to 30 µm hole with complex shapes

- SS manufacturing up to 58 HRC

Characterization

- Density profile

- Interferometry from Phasics

Examples of nozzles complex shapes manufacturing

Specific nozzles for interaction regimes

To make it possible for the experimentalist to explore precise interaction regimes and physics, SourceLAB developed a unique class of nozzles associated to precise manufacturing capabilities, that give access to specific plasma shapes and densities.

Each nozzle of the class can be easily fixed on a rapid valve to get the desired output flow.

In particular, our new class SL-Noz-Comp (see specifications), is specially designed to generate sub- 100 μm plasma of near-critical density, without external shocks from blades or cooling devices.

Importantly, it produces sub-μm dense plasmas at a larger distance from the nozzle exit than the standard 400 μm sonic nozzle. Therefore the lifetime of the nozzle is significantly increased while ensuring outstanding performances.

Corresponding atomic density map and projection measured at the exit.

The backing pressure reads 320 bar.

Shadowgram of a typical SL-Noz-Comp jet in vacuum.

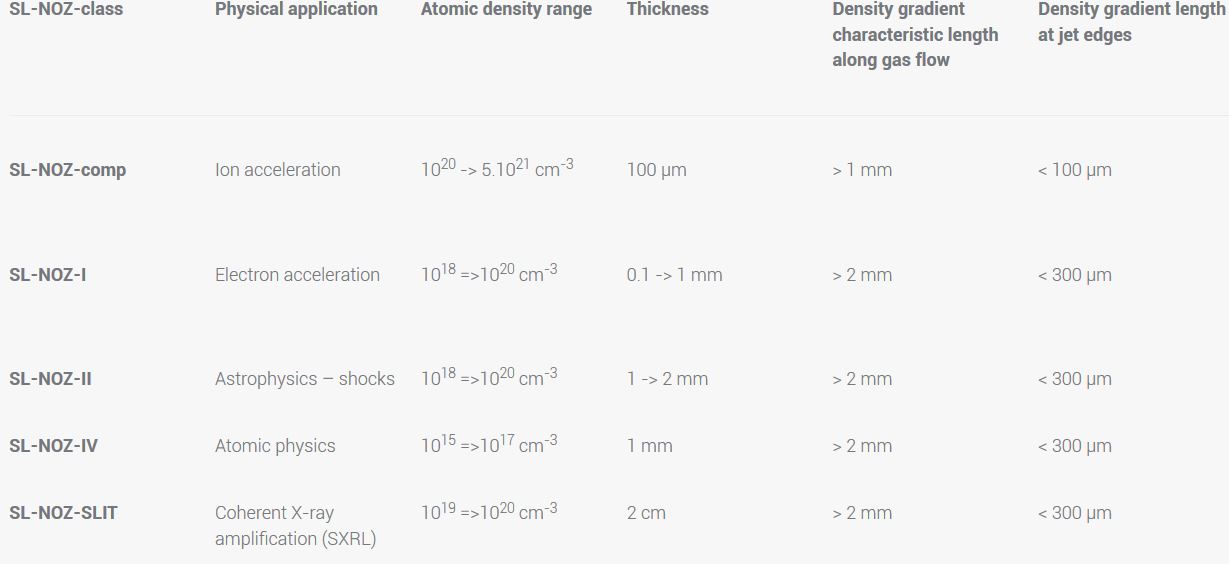

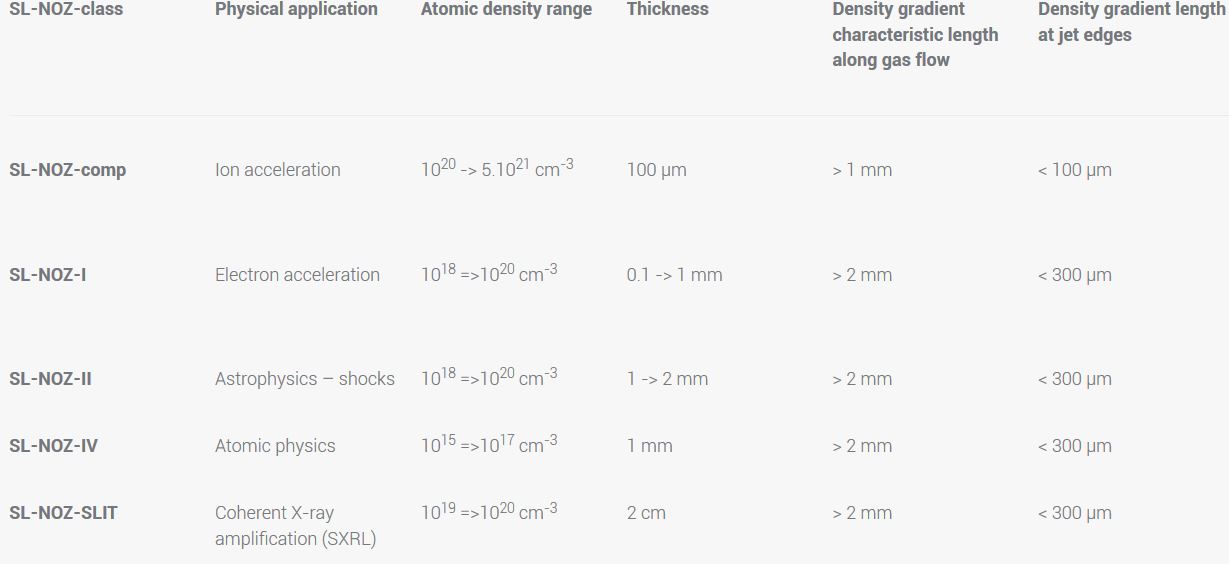

Detailed specifications:

SL-NOZ-class

Physical application

Atomic density range

Thickness

Density gradient characteristic length along gas flow

Density gradient length at jet edges

SL-NOZ-comp

Ion acceleration

1020 -> 5.1021 cm-3

100 μm

> 1 mm

< 100 μm

SL-NOZ-I

Electron acceleration

1018 =>1020 cm-3

0.1 -> 1 mm

> 2 mm

< 300 μm

SL-NOZ-II

Astrophysics – shocks

1018 =>1020 cm-3

1 -> 2 mm

> 2 mm

< 300 μm

SL-NOZ-IV

Atomic physics

1015 =>1017 cm-3

1 mm

> 2 mm

< 300 μm

SL-NOZ-SLIT

Coherent X-ray amplification (SXRL)

1019 =>1020 cm-3

2 cm

> 2 mm

< 300 μm

- I.Prencipe et al

Targets for high repetition rate laser facilities: needs, challenges and perspectives

High Power Laser Science and Engineering, 5, e17 (2017)

- E. Guillaume et al.

Physics of fully-loaded laser-plasma accelerators

Phys. Rev. ST Accel. Beams, Volume 18, 061301, June (2015)

- Overview

-

Unique capabilities for nozzle manufacturing

SourceLAB developed a range of solutions for nozzle manufacturing and characterization:

Flow simulation

- From a CAD file or specifications

Manufacturing

- Metal, ceramic, 3D printing

- Down to 30 µm hole with complex shapes

- SS manufacturing up to 58 HRC

Characterization

- Density profile

- Interferometry from Phasics

Examples of nozzles complex shapes manufacturing

Specific nozzles for interaction regimes

To make it possible for the experimentalist to explore precise interaction regimes and physics, SourceLAB developed a unique class of nozzles associated to precise manufacturing capabilities, that give access to specific plasma shapes and densities.

Each nozzle of the class can be easily fixed on a rapid valve to get the desired output flow.

In particular, our new class SL-Noz-Comp (see specifications), is specially designed to generate sub- 100 μm plasma of near-critical density, without external shocks from blades or cooling devices.

Importantly, it produces sub-μm dense plasmas at a larger distance from the nozzle exit than the standard 400 μm sonic nozzle. Therefore the lifetime of the nozzle is significantly increased while ensuring outstanding performances.

Corresponding atomic density map and projection measured at the exit.

The backing pressure reads 320 bar.

Shadowgram of a typical SL-Noz-Comp jet in vacuum.

- Specifications

-

Detailed specifications:

SL-NOZ-class

Physical application

Atomic density range

Thickness

Density gradient characteristic length along gas flow

Density gradient length at jet edges

SL-NOZ-comp

Ion acceleration

1020 -> 5.1021 cm-3

100 μm

> 1 mm

< 100 μm

SL-NOZ-I

Electron acceleration

1018 =>1020 cm-3

0.1 -> 1 mm

> 2 mm

< 300 μm

SL-NOZ-II

Astrophysics – shocks

1018 =>1020 cm-3

1 -> 2 mm

> 2 mm

< 300 μm

SL-NOZ-IV

Atomic physics

1015 =>1017 cm-3

1 mm

> 2 mm

< 300 μm

SL-NOZ-SLIT

Coherent X-ray amplification (SXRL)

1019 =>1020 cm-3

2 cm

> 2 mm

< 300 μm

- Downloads

-

- Publications

-

- I.Prencipe et al

Targets for high repetition rate laser facilities: needs, challenges and perspectives

High Power Laser Science and Engineering, 5, e17 (2017)

- E. Guillaume et al.

Physics of fully-loaded laser-plasma accelerators

Phys. Rev. ST Accel. Beams, Volume 18, 061301, June (2015)

- I.Prencipe et al