PARTICLE SOURCES

Revolutionary source for Non Destructive Testing by X-Ray tomography

More and more actors of the industrial and research world demand on complete and secure techniques to control the integrity of some critical components.

It is particularly the case for industrials sectors like:

– Aerospace

– Defense

– Naval industry

– Nuclear industry

– Petrochemical industry

-…

These industries use all the range of NDT techniques but when it comes to thick metallic parts or complex shaped composite equipment, in a context where resolution maters, only the X-ray radiography technique is adapted.

SourceLAB developed an X-Ray tomography source, based on laser-plasma interaction, offering unprecedented resolution, high-flux and complete security, as well as a great flexibility through a direct access to numerical detectors for on-line diagnostics

0-20 MeV energy, tunable (up to 1 m thick Stainless Steel part)

State of the art platform for NDT services

Constant resolution < 100 µm

Micro-tomography capabilities at low energy

0-20 MeV energy, tunable (up to 1 m thick Stainless Steel part)

State of the art platform for NDT services

Constant resolution < 100 µm

Micro-tomography capabilities at low energy

The first X-Ray tomography platform based on laser-plasma interaction

The laser-plasma technology offers unique performances for industrial Non Destructive Testing.

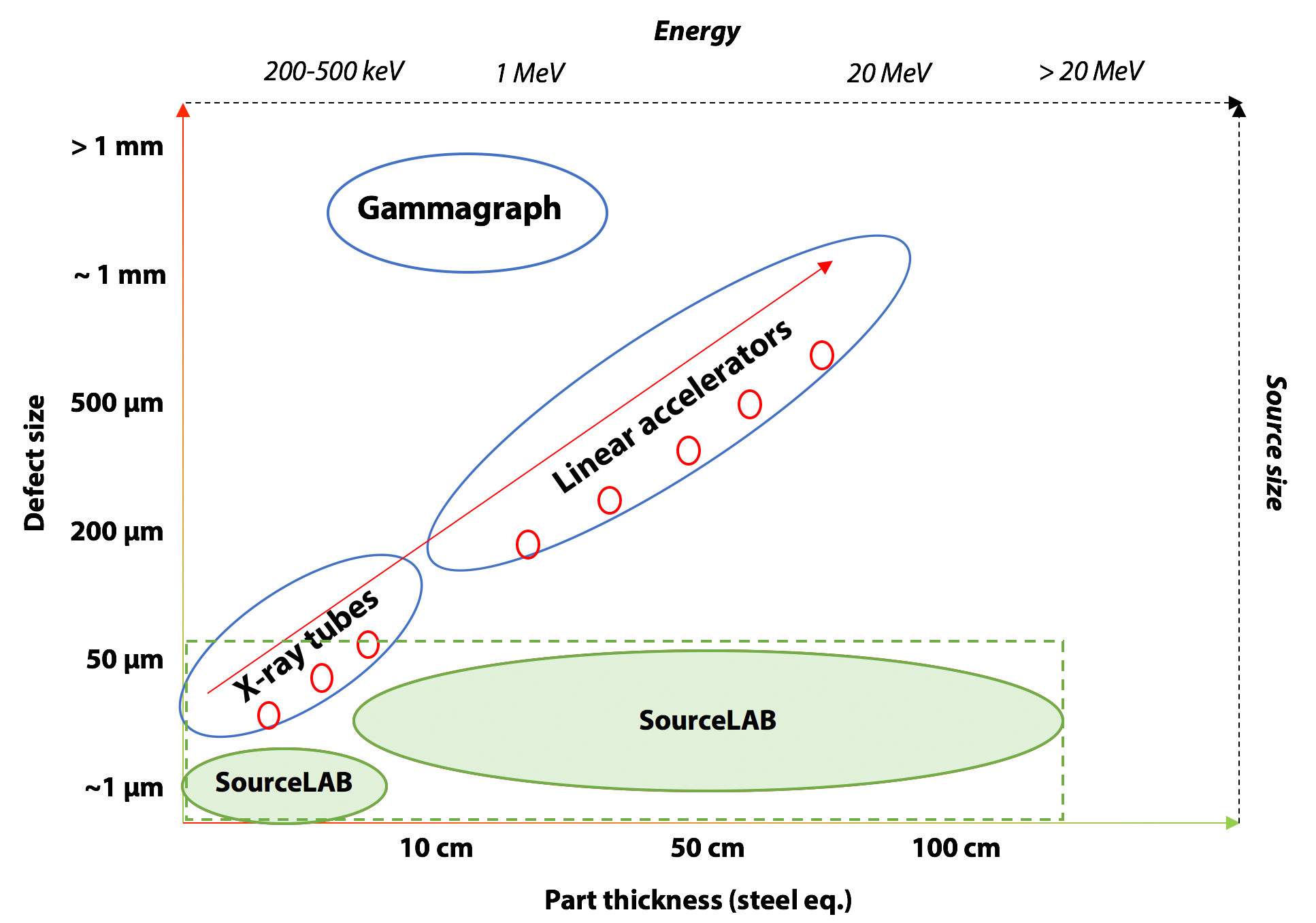

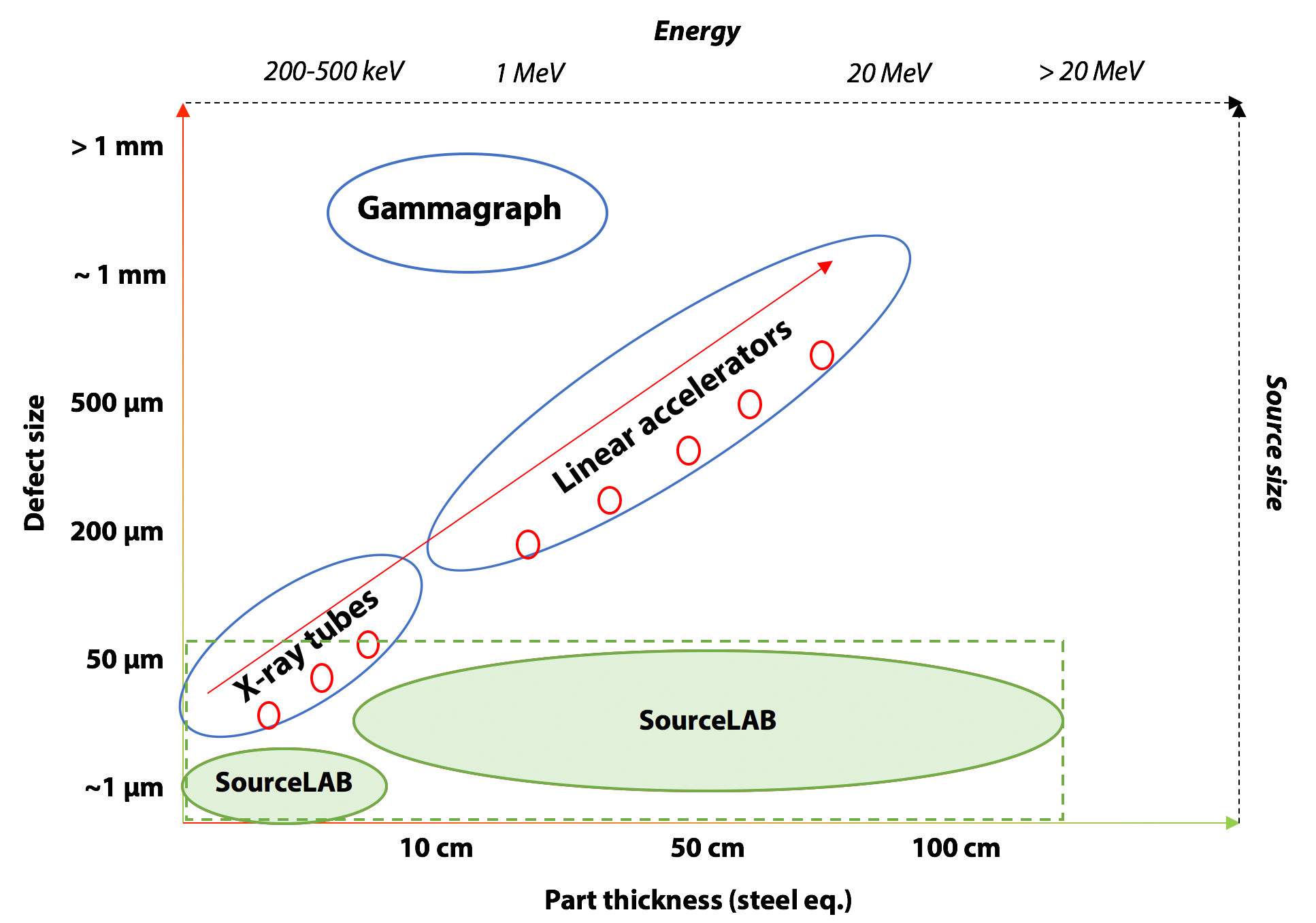

The specifications of the current X-Ray sources technologies (X-Ray tubes, gammagraphs, linear accelerators) do not fully meet users needs. In particular, the users face the following limits:

- the higher the energy, the worse the resolution

- no access to real micro-tomography

- one different system by energy level

With laser-plasma acceleration, these limits do not exist anymore. Industries with heavy and complex parts can now have access to revolutionary performances.

Specifications of the SourceLAB NDT X-Ray source compared to current technologies. A unique system covers all the energy range with a constant resolution far better than existing systems.

Located in Palaiseau , our platform is a state-of-the-art equipment to provide NDT services to industrial users:

-Radio-protected facility

-No limitation on material type

-Parts up to 1 m3 and 1 ton

-Numerical detection (tomography)

![]()

Detailed specifications:

Source type: Gamma / X-Ray tomograph by laser-plasma acceleration

Source energy: From 0 to 20 MeV, continuously tunable

Source resolution: ~50 µm constant at high energy (0-20 MeV)

Micro-tomography capabilities at low energy (~1µm @400 keV)

Source flux: > 10 gy/min/m

Part material: No limitation

Part size: Up to ~1 m3 for 1 ton

Part thickness: Up to 1 m stainless steel

Detection: Numerical, full 3D reconstruction

No download available.

- A. Döpp et al.,

A bremsstrahlung gamma-ray source based on stable ionization injection of electrons into a laser wakefield accelerator,

Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, Elsevier, published online 6 February (2016)

- E. Guillaume et al.,

Physics of fully-loaded laser-plasma accelerators,

Phys. Rev. ST Accel. Beams, Volume 18, 061301, June (2015)

- Overview

-

Revolutionary source for Non Destructive Testing by X-Ray tomography

More and more actors of the industrial and research world demand on complete and secure techniques to control the integrity of some critical components.

It is particularly the case for industrials sectors like:

– Aerospace

– Defense

– Naval industry

– Nuclear industry

– Petrochemical industry

-…

These industries use all the range of NDT techniques but when it comes to thick metallic parts or complex shaped composite equipment, in a context where resolution maters, only the X-ray radiography technique is adapted.

SourceLAB developed an X-Ray tomography source, based on laser-plasma interaction, offering unprecedented resolution, high-flux and complete security, as well as a great flexibility through a direct access to numerical detectors for on-line diagnostics

0-20 MeV energy, tunable (up to 1 m thick Stainless Steel part)

State of the art platform for NDT services

Constant resolution < 100 µm

Micro-tomography capabilities at low energy

0-20 MeV energy, tunable (up to 1 m thick Stainless Steel part)

State of the art platform for NDT services

Constant resolution < 100 µm

Micro-tomography capabilities at low energy

The first X-Ray tomography platform based on laser-plasma interaction

The laser-plasma technology offers unique performances for industrial Non Destructive Testing.

The specifications of the current X-Ray sources technologies (X-Ray tubes, gammagraphs, linear accelerators) do not fully meet users needs. In particular, the users face the following limits:

- the higher the energy, the worse the resolution

- no access to real micro-tomography

- one different system by energy level

With laser-plasma acceleration, these limits do not exist anymore. Industries with heavy and complex parts can now have access to revolutionary performances.

Specifications of the SourceLAB NDT X-Ray source compared to current technologies. A unique system covers all the energy range with a constant resolution far better than existing systems.

Located in Palaiseau , our platform is a state-of-the-art equipment to provide NDT services to industrial users:

-Radio-protected facility

-No limitation on material type

-Parts up to 1 m3 and 1 ton

-Numerical detection (tomography)

- Specifications

-

Detailed specifications:

Source type: Gamma / X-Ray tomograph by laser-plasma acceleration

Source energy: From 0 to 20 MeV, continuously tunable

Source resolution: ~50 µm constant at high energy (0-20 MeV)

Micro-tomography capabilities at low energy (~1µm @400 keV)

Source flux: > 10 gy/min/mPart material: No limitation

Part size: Up to ~1 m3 for 1 ton

Part thickness: Up to 1 m stainless steel

Detection: Numerical, full 3D reconstruction - Downloads

-

No download available.

- Publications

-

- A. Döpp et al.,

A bremsstrahlung gamma-ray source based on stable ionization injection of electrons into a laser wakefield accelerator,

Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, Elsevier, published online 6 February (2016)

- E. Guillaume et al.,

Physics of fully-loaded laser-plasma accelerators,

Phys. Rev. ST Accel. Beams, Volume 18, 061301, June (2015)

- A. Döpp et al.,